Soils are very important in the design and installation of SRWs.

Soils support walls, load walls, and in the case of reinforced walls, are part of the wall systems. Design of SRWs varies greatly depending on soils. With proper design, SRWs can be constructed in a wide variety of soil conditions.

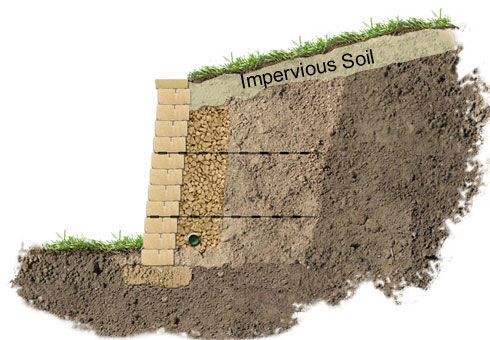

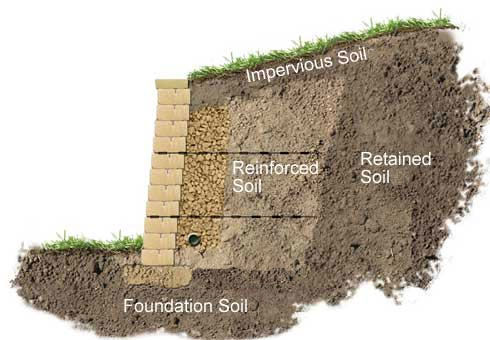

There are four main soil zones involved in SRW design (right). They are:

Identifying and using the correct soil type in each of these zones is critical to wall performance.

Soils generally are classified as one of four soil types: gravel, sand, silt or clay. When you can see the individual particles in the soil with the naked eye, such as gravel and sand, these soils are called coarse-grained. The grains in fine-grained soils, such as silt and clay, are too small to be seen. Fine-grained soils also tend to be "sticky" or cohesive.

Usually, coarse-grained soils such as gravel, provide the best working conditions because they place less load on the walls, require less soil reinforcement, are easier to compact and are less affected by water. SRWs also can be built with and around fine-grained soils if these soils are properly addressed in the wall design and installation.

Foundation soil

Foundation soil is the soil directly beneath

the wall system and supports the wall weight. Usually, foundation soil

is the existing, on-site soil.

Foundation soil must be stiff or dense, so that it is strong enough to

hold the wall weight without settling. Soft, loose, compressible, wet,

frozen or organic top soils are unacceptable for foundation soils. These

unacceptable soils must be excavated and replaced with properly

compacted soils, preferably granular soils.

If a wall needs to be built over previously placed fill, such as

utility-trench backfill or side-cast fill near a basement wall, it is

very important to ensure that this old backfill has been properly

compacted. If you are unsure, it's best to replace the backfill.

Reinforced soil

When building a taller wall that requires soil reinforcement, the

soil placed and compacted around the layers of reinforcement is called

reinforced soil.

The reinforced soil zone creates a gravity mass that becomes

part of the retaining wall, so it is important that the reinforced soil

is of high-quality material and is properly compacted. On-site soil may

be acceptable to be re-used for reinforced fill. However, sometimes the

reinforced fill must be imported from off-site.

Select granular soil is the best material for reinforced soil

because it interacts well with the soil reinforcement, compacts easily and is

less sensitive to moisture changes. However, fine-grained soil also can

be used as reinforced soil if properly addressed.

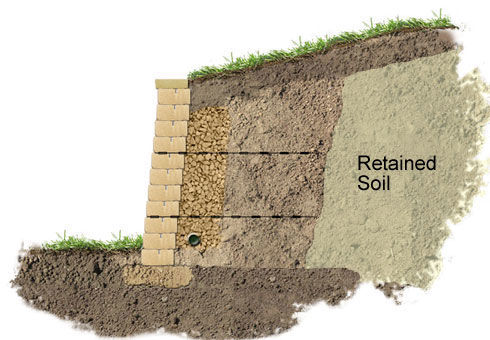

Retained soil

Retained soil is the soil directly behind the wall system that the wall holds in place, or retains.

In the case of an unreinforced wall, retained soil is the soil directly

behind the Standard units and drainage material. For reinforced walls,

retained soil is soil directly behind the wall system's reinforced soil

mass.

The type of soil in the retained zone determines how much load

the wall must resist. Proper identification of the retained soil is

critical to wall performance. The wall design is especially sensitive to

the retained soil type if there is a slope behind the wall.

Impervious soil

Impervious is soil through which water cannot pass. Impervious soil is used at the top of the wall to help seal it off. Impervious soil helps protect walls from stormwater run off by keeping water from entering behind and into the wall system. Impervious soil at the top of the wall should be graded to avoid water flows, concentrations or ponding behind retaining walls.